|

Search 650Rider.com and XS650.com using Google!

|

| |

|

|

|

| xs650 > > Motorcycle Systems > > Electrical > > Wire splicing |

|---|

| Author |

Message |

bennecc

Full Member

Joined: May 31, 2009

Posts: 57

|

Posted: December 22, 2009, 4:11 am Post subject: Wire splicing Posted: December 22, 2009, 4:11 am Post subject: Wire splicing |

|

| I apologize in advance for the silly question, but I'll ask it anyways. What is the preferred method of splicing one wire into another length of wire? As in, there is a red wire from my TCI box connected to a red wire on the coil, but somewhere along there the a wire from the kill switch needs to connect. How do I do this and have it look neat?

|

|

| Back to top |

|

|

despecial

Full Member

Joined: Sep 26, 2009

Posts: 232

Location: D20000

|

Posted: December 22, 2009, 5:23 am Post subject: Re: Wire splicing Posted: December 22, 2009, 5:23 am Post subject: Re: Wire splicing |

|

insulation - round double female or round single female

connection - round double female or round single female

insulation - round single male

connection - round single male

crimp and solder

_________________

Most motorcycle problems are caused by the nut that connects the handlebars to the saddle. |

|

| Back to top |

|

|

bennecc

Full Member

Joined: May 31, 2009

Posts: 57

|

Posted: December 22, 2009, 11:14 am Post subject: Re: Wire splicing Posted: December 22, 2009, 11:14 am Post subject: Re: Wire splicing |

|

| Thanks despecial, but I'm still confused.....what do I use to make a single wire "branch out" into two wires?

|

|

| Back to top |

|

|

acbanks

Full Member

Joined: Mar 21, 2009

Posts: 72

Location: Raleigh, NC, USA

|

Posted: December 22, 2009, 1:13 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 1:13 pm Post subject: Re: Wire splicing |

|

When I'm in a hurry I'll just go up to the next size crimp splice, twist the wires together and crimp them.

The best way of course is to twist the wires together, solder them and cover with heat shrink tubing.

I've had a hard time finding good bullet connections to replace the originals.

|

|

| Back to top |

|

|

bennecc

Full Member

Joined: May 31, 2009

Posts: 57

|

Posted: December 22, 2009, 2:28 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 2:28 pm Post subject: Re: Wire splicing |

|

| That's a good idea about just using a larger crimp splice, can't believe I didn't think of that. I was trying to figure out in my head how to head shrink what is essentially a "T" shape.

|

|

| Back to top |

|

|

KevC

Full Member

Joined: Nov 18, 2009

Posts: 13

Location: Herts, uk

|

Posted: December 22, 2009, 5:41 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 5:41 pm Post subject: Re: Wire splicing |

|

You should be able to find quality electrical connectors like the pics despecial posted, think mikesxs has them.

Replace a single female connector on your loom with a new double female and you then have a spare connector to wire up to with another single male.

Its harder to write than it is to actually do

|

|

| Back to top |

|

|

despecial

Full Member

Joined: Sep 26, 2009

Posts: 232

Location: D20000

|

Posted: December 22, 2009, 5:59 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 5:59 pm Post subject: Re: Wire splicing |

|

- actually, to instal a kill switch, you dont want to branch out into 2 wires as then the kill switch is effectively bypassed...cut the live wire feeding the TCI, fit a single female to the live end and a single male to the other, fit a single male to a wire running to the kill switch and a single female to the wire running back to the TCI feed...plug them together in a loop,power-kill-TCI...use insulators and the live side of any join should always be female

- you can also get triple connectors and insulators

- the problem with twisting wires together , soldering them and shrinkwrapping them is that if you have to remove the loom you have to cut the wires and repair them again-messy

_________________

Most motorcycle problems are caused by the nut that connects the handlebars to the saddle.

Last edited by despecial on December 22, 2009, 7:01 pm; edited 1 time in total |

|

| Back to top |

|

|

bennecc

Full Member

Joined: May 31, 2009

Posts: 57

|

Posted: December 22, 2009, 6:22 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 6:22 pm Post subject: Re: Wire splicing |

|

Well I thought I had it figured out until I read that last post....

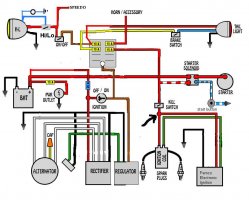

I am using the attached diagram. My original question was about how to make the connection indicated by the arrow. The hot red wire from the fuse box passes through the kill switch then splits to go to the coil and the TCI. The orange wire completes the loop that you're referring to?

| Description: |

|

| Filesize: |

66.42 KB |

| Viewed: |

419 Time(s) |

|

|

|

| Back to top |

|

|

pumps

650Rider Supporter

Joined: May 29, 2007

Posts: 1993

Location: Kansas City, Missouri, U.S.A.- 1977 XS650 "D" Standard

|

Posted: December 22, 2009, 6:47 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 6:47 pm Post subject: Re: Wire splicing |

|

If you look in despecials second picture on the left side there is a double female. Two round single males (bottom picture)will plug into the dbl female to "branch out into two wires."

_________________

You don't HAVE to be crazy to run into burning buildings, but it HELPS!

On an XS you won't pass yourself on the road everyday.

My Bikes |

|

| Back to top |

|

|

bennecc

Full Member

Joined: May 31, 2009

Posts: 57

|

Posted: December 22, 2009, 6:58 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 6:58 pm Post subject: Re: Wire splicing |

|

| Thanks pumps, that's what I was looking for. In the photo it looks the same as a single female quick disconnect terminal, that's what got me confused.

|

|

| Back to top |

|

|

despecial

Full Member

Joined: Sep 26, 2009

Posts: 232

Location: D20000

|

Posted: December 22, 2009, 7:03 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 7:03 pm Post subject: Re: Wire splicing |

|

- youre on the right track bennecc-i had a slight block that ive edited but the basics are correct

- the pictures show bullet type connectors not spade type

- the loop is completed by the earth or ground connection

_________________

Most motorcycle problems are caused by the nut that connects the handlebars to the saddle. |

|

| Back to top |

|

|

gordo

650Rider Supporter

Joined: Oct 09, 2008

Posts: 559

Location: CT.U.S.A.

|

Posted: December 22, 2009, 9:59 pm Post subject: Re: Wire splicing Posted: December 22, 2009, 9:59 pm Post subject: Re: Wire splicing |

|

When splicing into another wire, the best way to make the splice is to unsheath about 3/4 of an inch off the wire that is going to be spliced into. Then, remove about the same amount of plastic cover off the new wire, the one that's going to a new circut. Put the wire's together to form a T, with the new wire about half to 3/4 of the way up on the bare wire. Make 2 wrap's to the right of the T, then wrap the rest of the wire around the left side of the T. When going over to the left side, pass the wire under to connection, then come up on the other side. Solder the connection, and if you can find some, use heat shrinkable electrical tape. Or with regular tape, wrap up in the same maner as the connection was made. DO NOT be cheap on the tape, use quality tape such as 3M brand, because the 3 for a dollar roll's are junk.

If, when done soldering, you have sharp point's or stray wire coming from the connection, clean it up with either a fine file, sandpaper, or grinder, because the point's will poke thru the insulation,(tape ) and create a short.

Or, instead of that, you can get a block that is made specifically for that. The block's come in all different size's for different wire size's. Easy peasy, just cut the wire insert bothe ends into one side, then the new circut on the other.

Also, there is a product called liquid electrical tape. Work's ok, can be messy if your not carefull.

_________________

'80 G, |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

|

|

|

| |

Check out the new Honda CB750 Forum at CB750.com! A site dedicated to the great Honda SOHC and DOHC CB750.

Check out the new Yamaha XS400 Forum at XS400.com!

Yamaha xs650

xs650, xs, 650, forum, links, chopper, custom, yamaha, parts, forum, info,

information, bb, bulletin board, XS650 650Rider, Free Unrestricted xs650

forum, Personal photo albums, Post images in Forum, News columns, Daily blog,

Links, Event calendar, Information for Yamaha XS650

Interactive software released under GNU GPL,

Code Credits,

Privacy Policy

|